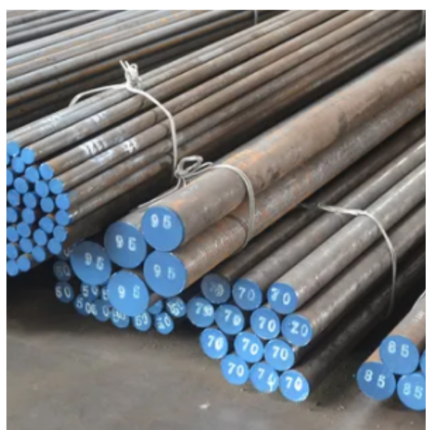

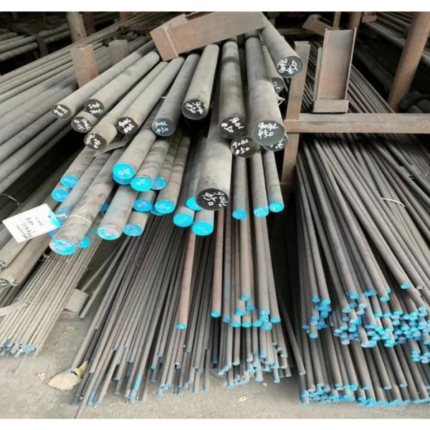

Description

Alloy steel S1 is a shock-resistant tool steel that is commonly used in the manufacturing of cold work tools, such as punches, chisels, and dies. It contains 0.5% carbon, 1.5% chromium, 0.25% molybdenum, and 0.5% vanadium as the primary alloying elements, which provide high hardness, wear resistance, and good toughness.

Alloy steel S1 can be heat-treated to achieve a wide range of mechanical properties, making it suitable for a variety of cold work tool applications. It is also known for its good machinability, which allows it to be easily shaped and machined.

Additionally, alloy steel S1 has good dimensional stability and can withstand high stress and shock loads, making it a reliable material for tooling. It also has good resistance to wear and abrasion, making it suitable for applications that involve heavy-duty machining and cutting.

Overall, alloy steel S1 is a widely used material in the tool and die industry. It offers a combination of high hardness, wear resistance, toughness, and shock resistance that makes it suitable for a range of cold work tool applications in different industries, including automotive, industrial manufacturing, and construction.

Reviews

There are no reviews yet.